The Advanced Technology Behind Molded Oil Bearings and Solid Lube Bearings

Author:DMAG Bearings Release times:2024.12.05

Author:DMAG Bearings Release times:2024.12.05

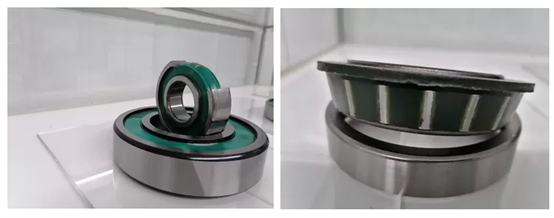

Bearings are an essential component in machinery, enabling smooth and efficient operations across industries. Recent advancements in bearing technology have introduced molded oil bearings, solid lube bearings, and solid oil bearings, which are revolutionizing the way industries approach lubrication and maintenance.

Molded oil bearings are a breakthrough solution for environments where traditional lubrication methods may fail. These bearings incorporate oil-impregnated polymer material that steadily releases lubrication during operation. Unlike conventional bearings, molded oil bearings offer:

For more information about high-quality solid oil-lubricated bearings, explore our product range of molded oil bearings designed to deliver top-notch performance.

Solid lube bearings are another innovative type of bearing that excels in harsh operating environments. These bearings utilize a solid lubricant to ensure consistent performance even in extreme temperatures or contamination-prone conditions. Key advantages include:

If you’re looking for reliable options, check out our solid lube bearings that are engineered for durability and performance in challenging applications.

Solid oil bearings take lubrication to the next level by embedding oil within a solid polymer matrix. This design ensures that lubrication remains constant, even under extreme conditions such as heavy loads or high speeds. Benefits of solid oil bearings include:

Discover how solid oil bearings can transform your operations with their unmatched reliability.

Whether you’re looking for molded oil bearings, solid lube bearings, or solid oil bearings, these advanced solutions are engineered to improve efficiency, reduce maintenance, and enhance the lifespan of your machinery. At MAG Bearings, we specialize in providing cutting-edge solutions tailored to meet the demands of modern industries.

Take the next step toward optimized performance—explore our range of solid oil-lubricated bearings today!

Conclusion

Molded oil bearings, solid lube bearings, and solid oil bearings are paving the way for more reliable and efficient machinery. With their unique features and advantages, they are the ideal choice for industries seeking to enhance performance and reduce maintenance efforts. Contact us to learn how these innovative bearings can make a difference in your operations.